Sometimes it’s hard to describe exactly what First Mode does, because we do so many different things. In this series, we’ll take a closer look at the nature of working at First Mode through the eyes of the people who work here. Today we talked to Krunal Desai, Director of Electrical Engineering at First Mode.

(Want to work with us? Check out our careers page.)

What makes working at First Mode a unique opportunity for an electrical engineer?

Really, there’s a couple themes. One is that you’re getting to work on clean technology and sustainability, but in a way that’s practical and pragmatic. There are a lot of places where you can do this type of work, and historically they’re supported by national labs, academia, or as a corporate side-project — not the core focus of an organization. Obviously, the renewed focus on climate change has begun to change that, and we’re fortunate to have large customers who are dead serious about decarbonization, which means that we have a very direct path to creating a product that people are interested in. These customers have shareholder and social pressure to get their act together in decarbonization if they wish to continue their work — they need social license to operate. That drives us to move a lot faster than the usual status quo.

Because of the position we’re in, we get to work with really interesting technologies here. We work with some of the largest fuel cell vendors, we work with several major lithium-ion battery vendors. That’s hundreds of kilowatts of fuel cells and megawatt-hours of batteries.

We also work very closely with a lot of electric vehicle component suppliers, working with their next-generation technology and adding it to our toolbox. So if you’re interested in integrating existing systems, you can do that here. We still design our own hardware, so if you’re interested in designing circuit boards, embedded computers, and the like, we create our own to tie together these off-the-shelf components. We also develop our software and firmware in-house, creating platforms that we can apply to all of our clean-technology projects.

We do a lot of stuff in-house because we have to, and we’re interested in creating platforms that apply to all the products that we work on — powerplants, and adapters for where those powerplants go, and so on. It may not be immediately obvious from our website, but even for our clean-technology projects, we design our own custom controllers, we write our own custom software, and then we also buy things to use. We always exercise a make-vs-buy trade for our hardware, and something we buy today may be something we make tomorrow.

The other key thing is that we’re generally tool-agnostic — we don’t have a horse in the race. We’re not a fuel cell company, or a battery company. We can combine as many fuel cells with as much battery power as we want, and we’ve combined diesel with those before. We just get to play with all of those things here.

Related story: Ars Technica: Massive mine truck and a Baja off-road racer both find use for fuel cells

Talk us through your typical day at First Mode.

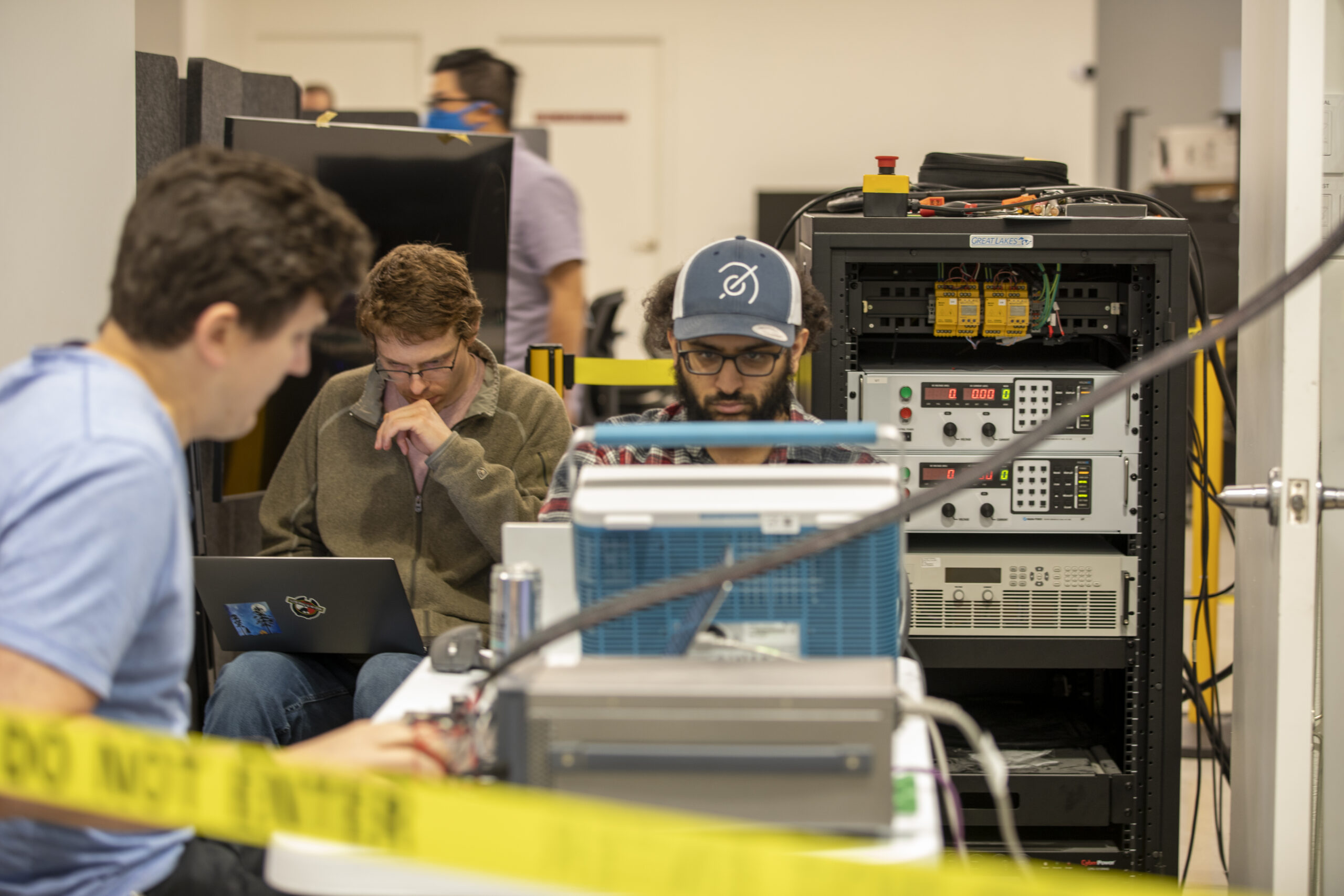

The variety of our work here is a very cool thing for electrical engineers. In one day you could be running a test on an 800 kW hydrogen power system in the morning, and then the hour after that you could be working on FPGA updates and development, and then you could be going to review the design of an enclosure, maybe an electromechanical assembly, and then you could be in a review for software running on that. And then at the end of the day you could be finishing a PCB layout with our Australian office.

I’ve definitely had days like that — it’s a non-stop rush, but cool to jump around the entire EE stack.

Tell me about the other electrical engineers you work with and the range of experience they bring to the team.

One of the favorite things about the team that we’ve built here is that we have a super-diverse set of backgrounds. It’s an opportunity to cherry-pick the best of different industries. I’ve got folks that work for me that came from industrial robotics, we’ve got folks who worked on medical devices, we’ve got automotive, aerospace — basically it’s like collecting Pokémon, getting the best of these things and then we get to put them all together. We’ve also got folks where engineering is their second, even third career — these folks often bring some of the most valuable insights to our problems.

We’re really big on making sure that we’re not just stacked up with ex-space or ex-automotive people, so all those ideas collide and we get to do things in a really interesting way, combining the best practices of factory automation and industrial robotics with, say, the best selection of automotive, and cherry-picking the rules that we follow with each one.

Related story: Meet Spencer Berglund, First Mode Electrical & Embedded Systems Engineer

How have those backgrounds impacted some of the technologies we’ve designed?

The entirety of our hydrogen haul truck project has been a collision of backgrounds. My background is automotive, industrial equipment, consumer electronics, and aerospace. Then, a lot of the core folks on that project came from industrial robotics and heavy trucks. That was a great combination because we essentially had to build a mobile, utility-scale power plant. That hits a lot of notes from industrial automation that we combined with the automotive side of things to make the technology mobile. That delivered some beneficial design choices. It’s a continuous process: We like to iterate quickly so we can keep trying new things.

In your own words, how would you describe what we do at First Mode?

We’re a zero-emission and sustainability company, and we build a variety of solutions for that purpose. We might do battery-only work, we might do hydrogen-only projects, but we build zero-emission solutions. A lot of companies say that, but I’d say the emphasis is that we do build it, just south of the sports stadiums in Seattle. We don’t just write up a giant specification package and then have someone else build or contract it. We have local vendors and suppliers that fab our structures or build our PCBAs, but we design them here, and we build and test here.

How has your experience at First Mode compared to your expectations?

I was the only EE when we started; over the past three years that’s built up to nearly 25 EEs, and it’s been very rapid growth. It’s all about learning how to build a team and set it up for success, setting up processes and infrastructure that act as force multipliers for the team, something that can take on all of the projects we have lined up to work on next.

When we first moved into our manufacturing facility in south Seattle, I just took all the stuff from my garage there for us to use before we could start to buy our own things. Now we have a state-of-the-art facility with a clean room and test cell, and we’re expanding into another facility next door. That bootstrapping adventure has been pretty fun.

Related story: A Seattle Manufacturing Lab Built for Clean Tech Development

What’s great about the First Mode culture?

We have an irreverent culture; nothing is sacred. On the EE team, we spitball stupid ideas all the time. It’s just a comfortable environment, where if you throw out a stupid idea, we’ll think and chuckle about it, have a bit of a “Well, actually…” moment, but it doesn’t get personal. That starts from the top — I’m more than happy to think out loud and toss out ideas to see what sticks, and culturally we’re talking about abstract technical concepts, not the people behind them. We explore what’s out there. We’re building unique things and everyone is always interested in ways to optimize and improve them. We try out new and interesting technologies, kit-bashing things together from all the different industries, because no one is telling us how to do things yet. I think we’ve accidentally invented perpetual motion or energy machines a couple times. We’ve definitely gone down rabbit holes where we’ve tried to overdesign and invent the world’s best light switch — but now all of our future projects will have a bullet-proof way of doing something as simple as turning on and off in a high-reliability, safety-critical fashion.

What types of EEs do best at First Mode?

The attributes with the highest correlation coefficient from our core values to doing well here are curiosity and flexibility. Because we’re usually doing prototype development and the requirements are in flux, we need people who are curious enough to go figure out what the right answer is and then flexible enough to react when things change. I like people who go down Wikipedia rabbit holes to not only learn about their technology but end up learning about the history and context around it. Most problems are not purely technical — they often are about people and the society we’ve built. Context is key, and curiosity helps you get to the bottom of it. Our most successful people are tolerant to ambiguity — it’s not always clear what the next steps are. If you’re used to crunching through a backlog of JIRA tickets, this may not be the right place. If you can tackle a problem and help decompose it to figure out what needs to be done — this is the right place for you.

And of course, with our other values — our best engineers are also honest, humble and simply willing to talk openly about whatever they are working on. Hiding schedule problems and reporting only good news doesn’t work well here — we encourage and reward every person at the company to be the squeaky wheel and raise a flag when something is wrong.

There are a lot of industries out there and having a wider variety of those people on our team is always better. The other thing I never ask for on my job postings is a college degree — I personally don’t really care where you went to school. Extracurriculars are interesting — Formula SAE, Solar Car — as long as you’ve done something, I don’t care if you have an English degree, or any degree. Problem-solving skills, technical talent, curiosity, and flexibility are what matter here.

Related story: Meet Paige Northway, Ph.D.: Systems Engineer at First Mode

How can engineers here expand into other disciplines when they want to?

Here, we’re not siloed. If you’re an EE, the expectation is that you’re going to talk to your mechanical colleagues, you’re going to form small teams, you’re going to think about thermal or vibration or whatever other system-level impacts exist. If there’s something you’re interested in learning about, you can just go to another desk and talk to someone, and they’ll be happy to fill you in on it — almost too happy. And by that, I mean that we mostly have folks who will set their own work and problems aside to help you out. Our positions here are tailored to each person we hire, so as they come in the next person’s role is influenced by that and so on.

What problems are you most excited to see First Mode working on in the coming year?

We have what I would describe as a business-to-business opportunity in decarbonization; consumers, on the other hand, are fickle. Much bigger organizations are tackling the problem of electric vehicles and selling them to consumers. They’re high-volume goods, and capital intensive, and there are century-old companies addressing that need.

With the B2B opportunity, I’m referring to those big companies with vehicle fleets that have no one addressing how to decarbonize them. These vehicles are key money-making assets for these organizations, represent a massive source of emissions, and we’re one of the few companies helping them out with innovative solutions and products. The scale of heavy industry is such that even a small percentage change in an organization that moves billions of tons of rock in a year is a big one, so getting to work on decarbonizing that is a great opportunity.

It’s almost too perfect — we have a great technical culture, are a close-knit group of folks, compensate competitively, and our work is objectively going to help improve the world.

Related story: GeekWire: First Mode Building Hydrogen Fuel Cell for One of the Biggest Zero-emission Vehicles on Earth